Sawmill Equipment For Sale

3781 Results Found

$ 6,825

LHI 4,500 # Scissor LiftSimple Design, Low Cost, High Performance w/ Off-The-Shelf Parts so you can keep it running years from now Specification: -- 4,500 Lbs weight capacity. -- 48" x 96" Smooth steel platform. -- Lowered height 9-1/2" raised height 49". -- Travel speed: 1/2" per second up -- Foot pedal control.Available Options: -- Automatic Down Indexing -- Automatic Up Indexing -- Automatic Up/Down Indexing

$ 54,780

LHI RFPR 102/10 MULTI-BLADE PANEL SAW: with 102" of usable width cutting capacity. Specifications: -- (1) 40 HP main arbor motor for 1/8" min. - 4-1/4" max. material thickness; min. panel length 30"; 102" of usable width cutting capacity. -- 12" Dia max. blade capacity; 1.25" minimum spacing between the blades; -- 3-15/16" Dia. arbor with 1-15/16" precision arbor bearings; -- Positive powered steel contact feed rollers with (8) Polyurethane drive rollers; fixed feed speed of 80 FPM. -- Includes (6) arbor collars - blades not included. -- Complete with:(2) 4" dia dust collection ports on top and (1) 8" dust collection port on bottom. Total recommended 2,200 CFM.Available Options: -- Blade Box & "Quick Change" Arbor Cart and Trolley $12,590.00 each -- Arbor Carts modifications to accept 12" dia. blades $700.00 each -- Single Point Height Adjustment $ 6,000.00 each -- "Quick Change" set up kit (includes belt guide, belt tensioner, and hydraulic arbor lock) $3,695.00 each -- Tandem 8000# capacity infeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt, 31" x 192" platform and cross bars for fork truck entry $14,495.00 each -- Tandem 8000# capacity outfeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt with 48" x 192" platform and beveled crossbars for fork truck entry and auto down indexing $16,390.00 each -- Drag Chain Feeder Conveyor - Roller conveyor transfers sheets to in-feed of saw and dog chains align and start the sheets into the saw feed rolls. Recommended with 102" wide machines, $18,800 Tooling Cost: -- Carbide Tip Blades 10" dia. x 40-tooth thin kerf blades $125.00 each -- Saw Blade Tooling Collars $125.00 eachOn average this machine will cut a bundle (42 sheets) of 3/4" Plywood. LVL, PB, MDF or OSB into narrow strips in 4 minutes or less.NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

$ 7,725

LHI 6,000 # Scissor LiftSimple Design, Low Cost, High Performance w/ Off-The-Shelf Parts so you can keep it running years from now Specification: -- 6,000 Lbs weight capacity. -- 48" x 96" Smooth steel platform. -- Lowered height 9-1/2" raised height 49". -- Travel speed: 1/2" per second up -- Foot pedal control.Available Options: -- Automatic Down Indexing -- Automatic Up Indexing -- Automatic Up/Down Indexing

$ 167,985

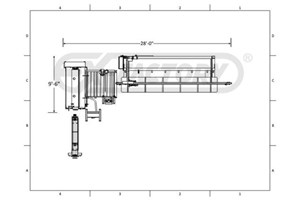

LHI 72" RFPR Wide Arbor Roll Feed Gang Panel Ripper with Custom 5' x 16' Automated Infeed -- Specifications: -- 30 HP Arbor Motor; 1/8" min. to 1-1/4" max. material thickness and 72" cutting width. -- 10" Dia. blade design cuts thru max. 2" thickness; -- 3-15/16" dia. arbor with 72" of usable width cutting capacity, min. panel length 30". -- 1-15/16" FAFNIR arbor bearings; with (8) steel feed rollers on 6" centers; fixed feed speed of 80 FPM -- 47-1/4" working height -- (1) Arbor Cart is included -- (2) 4" Dia. dust collection ports on top and (1) 8" dust collection port on bottom. Recommended 1,500 CFM Includes the Following Optional Items: -- 5-Strand powered Chain Deck; 12' long; arranged to feed 5' x 16' packages onto the Scissors Lift. Complete with controls for forward, reverse, and jog. -- 5-Sections of Gravity Rollers on Scissors Lift Deck -- 8,000 lbs. Infeed Tandem Scissors Lift with 5' x 17' Deck and 2-HP, 3-Phase Motor. Lift includes a backstop for initial alignment at the Rake Feeder -- (8) Polyurethane Rollers on 6" centers -- Variable Feed Speeds from 10 to 80 FPM. -- Rake Feeder for 16' long panels -- Auto-cycle for Rake Feeder. -- 6' Line Up Conveyor with Fence and Powered Pinch Roll Included Tooling: -- (36) Standard Saw Collars for Ripping -- (72) Standard 10" Sawblades for Ripping (Includes a spare set) -- (37) Standard Throat Plates for RippingQuick Setup Kit Included, Contains the Following -- Belt guide -- Belt Tensioner -- Hydraulic Arbor LockAdditional Arbor Setup Included. Contains the Following: -- Arbor Cart -- Cart -- Blade Box -- Arbor -- Bearings -- Sheave -- Throat Plate Rack -- (6) Throat Plates PRICE REFLECTS FACTORY'S 7% MATERIALS SURCHARGE ON $156,995, OR $10,990

Call for Price

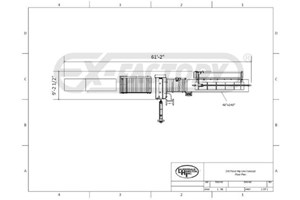

LHI MODEL RFPR AUTOMATED PANEL RIP SYSTEM --Arranged for up to 5/8"; Thick x 52"; Wide x 18’ Long Panels as follows: AUTOIMATIC INFEED SYSTEM, INCLUDES: --Rake Feeder for up to 18’ Long Sheets --Automated Feed Cycle Controls --Turnkey Controls, Plug it in and Run --1 HP, 3-Phase, 460-Volt Operation 6’ ALIGNMENT CONVEYOR, INCLUDES: --Gravity Roller Frame with 60"; Wide Rollers --Alignment Fence --Spring Loaded “Feather"; to Keep Sheets Tight to the Alignment Fence --Powered Feed Wheel to Push Sheets into the Ripsaw --2 HP, 3-Phase, 460-Volt Operation TANDEM INFEED SCISSORS LIFT --8,000 LBS. Capacity --30"; x 204"; Platform With 62"; Rails Mounted Across the Lift for Fork Lift Entry. Rails are Evenly Spaced Down the Length of the Lift --62"; x 204"; Useable Deck Size. --Automatically Raised and Lowered by Signals from the Sheet Feeder --2 HP, 3-Phase, 460-Volt Operation TANDEM OUTFEED SCISSORS LIFT --8,000 LBS. Capacity --30"; x 204"; Platform With 62"; Long Rails Mounted Across the Lift for Fork Lift Entry. Rails are Evenly Spaced Down the Length of the Lift --62"; x 204"; Useable Deck Size. --Automatically Lowers by Signals from Auto-Down Index Control Unit --2 HP, 3-Phase, 460-Volt Operation --OPTIONAL: 4-Sided “Accordion Skirts"; for each Tandem Lift Table, add $2.650 per lift RFPR" ROLL FEED PANEL GANG RIP SAW --50 HP Main Arbor Motor --1/8" Min. To 1-1/4" Max. Material Thickness x 72" Cutting Width --10" Dia Blade Design; 3-15/16" Dia. Arbor with 72" of Usable Width Cutting Capacity --Min. Panel Length 30". --1-15/16" FAFNIR Arbor Bearings --(8) Polyurethane Feed Rollers on 6" Centers --Variable Feed Speeds Via VFD --(1) Quick Blade Change-Out Kit --(1) Additional Arbor Cart --(2) 4" Dia. Dust Collection Ports on Top and (1) 8" Dust Collection Port on Bottom. Total Recommended 1,500 CFM. TOOLING: --(20) Saw Collars, Mount Directly to the Arbor with a Set Screw --(20) Saw Blades Configured for Clean Cuts on Your Panels

$ 117,000

LHI RFPR-72/16 "HEAVY DUTY" MULTI-BLADE PANEL RIP SAW (W/LOADING/UNLOADING): -- Specifications (1) 30 HP Main arbor motor for 1" min. - 5" max. material thickness;16" Dia max. blade capacity with 1.25" minimum spacing between the blades;Minimum panel length 30" with 72" of usable width cutting capacity.3-15/16" Dia. arbor with 1-15/16" precision arbor bearings;Positive powered steel contact feed rollers with (8) adjustable Polyurethane drive rollers;Variable feed speed to max 80 FPM.Available Options Include:Single point height adjustment for materials from 1" to 5" thickness using customer supplied 16" dia blades(note: Ripping widths can never be less than one-half the material thickness).(1) "Quick Change" arbor cart trolley and blade box for QC set ups.(12) Saw collars to attach the customer supplied 16" dia. diamond blades to the arbors(1) In-feed Scissors Lift with auto cycle controls(1) In-feed 6' conveyor with alignment fence and powered assist feed(1) Auto sheet feeder with auto cycle controls(1) Out-feed Scissors Lift with 4 x 8 roller top.Installation technical assistance for $125/Hr plus travel time and expenses, payable upon competition of services. NOTE:Quote is valid for 30-days;Quoted price is FOB, Factory;Customer is responsible for off-rigging cost at their facility;Customer is responsible for spotting the machine to its final resting place with adequate floor foundationCustomer is responsible for adequate electric, air & dust control supply upon technician's request:Warranty: 1-yr mechanical parts (electrical controls excluded);Delivery to Customer's facility is approx 17 weeks from receipt of funds;Quote assumes customer will deliver material for testing & run-off procedures (if required);NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

LHI RFPR 72/12 "HEAVY DUTY" MULTI-BLADE PANEL SAWSpecifications -- (1) 50 HP main arbor motor for 1/8" min. - 2" max. material thickness; 12" Dia max. blade capacity with 1.25" minimum spacing between the blades; Minimum panel length 30" & 72" of usable width cutting capacity. -- 3-15/16" Dia. arbor with 1-15/16" precision arbor bearings; positive powered steel contact feed rollers with (8) Polyurethane drive rollers; variable feed speed to max 80 FPM. -- (1) "Quick Change" arbor cart trolley and blade box for 9 1/2" cutsOn average this machine will cut a bundle (42 sheets) of 3/4" Plywood. LVL, PB, MDF or OSB into narrow strips in 4 minutes or less.Available Options: -- Blade Box Arbor Cart and Trolley $ 12,590.00 each -- Arbor Carts modifications to accept 12" dia. blades $ 700.00 each -- Single Point Height Adjustment $ 6,000.00 each -- "Quick Change" set up kit (includes belt guide, belt tensioner, and hydraulic arbor lock) $ 3,695.00 each -- Tandem 8000# capacity infeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt, 31" x 192" platform and cross bars for fork truck entry $ 14,495.00 each -- Tandem 8000# capacity outfeed Scissors Lift, 2 HP, 3 Phase, 230/460 Volt with 48" x 192" platform and beveled crossbars for fork truck entry and auto down indexing $ 16,390.00 eachTooling Cost: -- Carbide Tip Blades 12" x 40T x 4 3/16 bore with TCG and 3 pin holes $ 125.00 each -- Saw Blade Tooling Collars $ 125.00 each -- Actual Model is LAUDERDALE-HAMILTON RFPR "HEAVY DUTY" 12 Panel Rip SawNOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

$ 239,800

LHI 96" x 60" ANGULAR TYPE RIP & CROSS-CUT SYSTEM: Specifications: -- Automatic Angular Rip & Crosscut 5-Position System; max. panel size of 8' (96") long x 5' (60") wide x 1" - 4" thick; 1.25" minimum spacing between the blades; variable feed speed from 0 - 150 FPM. This system will process a unit of material in approx. (7) Min. -- Pos. # 1: LHI Automatic Staging/Infeed/Transfer & Panel Rake Feeding System: 10' (120") Long, powered 3-chain staging conveyor; (2) units can be preloaded while (1) unit is in process. Automatic up-indexing 4,500 Lbs capacity Scissors Lift with auto. rake infeed system: infeed rake system designed with a thin material device that can automatically load material as thin a 1/8". -- Pos. # 2: LHI "72": 72" Arbor length designed for panels up to max. of 5' (60") wide, min. panel length 30"; 40 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation. 2-3/4" Dia. arbor with 1-15/16" "Fafnir" arbor bearings; positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia. vertical dust outlets with an easy access strip separator box. -- Pos. # 3: LHI Cross-Transfer System: Transfer conveyor with panel hold-down & chain drive system to change direction 90° & automatically feed LHI 102". -- Pos. # 4: LHI "102": 102" Arbor length designed for panels up to max. 8' (96") long; 30 HP main arbor motor; 1/8" min. - 1" max. material thickness with no adjustment needed over a 3/8" thickness variation; 2-3/4" dia. arbor with 1-15/16" "Fafnir" arbor bearings. Positive non-marking steel contact feed rollers with (optional) poly-covering, driven from top & bottom. Includes: (6) blade collars; (2) 6" dia vertical dust outlets with an easy access strip separator box. -- Pos. # 5: LHI Stacking & Outfeed Transfer System: Auto. down-indexing 4,500 Lbs cap. Scissor Lift; (4) adjustable alignment posts & (4) bin separators to keep processed stacks square. 98' (96") Long outfeed gravity conveyor.Operating System: -- (1) LHI ALLEN-BRADLEY "Inter-Link" PLC for simple single-operator management of the entire system from (1) central control.NOTE: ...Attached description & pictures are for INFO purposes only; ...a NEW System can be modified to your exact specifications!NOTE: PRICING DOES NOT REFLECT FACTORY'S 10% MATERIALS SURCHARGE

$ 43,600

LHI RFPR-72/10 MULTI-BLADE PANEL SAW: Specifications: -- 40 HP main arbor motor; 1/8" min. - 1-1/4" max. material thickness; 10" dia blade with 1.25" minimum spacing between the blades; -- 3-15/16" Dia. arbor with 72" of usable width cutting capacity, min. panel length 30"; -- 1-15/16" precision arbor bearings; positive powered steel contact feed rollers; -- Fixed feed speed of 80 FPM. Blades & collars: -- Thin kerf 10" dia x 40-tooth x 4.18" bore non-split blades with quick & easy setup for fast blade positioning/removal (blades not included). -- Blades & collars are sold separately & not included in the machine price; 10" dia. x 40-tooth thin kerf blades, please add ...$ 105 ea.;1.25" wide x 4.18" bore blade collars, add ...$ 145 each. Complete with: -- (2) 4" dia dust collection ports on top and (1) 8" dust collection port on bottom. Total recommended 2,200 CFM -- Actual Model is LHI RFPR-72/10 Roll Feed Panel Saw. Available Options at additional cost: -- 110 V Infeed Scissor Lift with foot pedal controls or automatic up-indexing; 110 V Outfeed Scissor Lift with automatic down-indexing;Assortment of blade thicknesses & diameters; Split blade & collar system; Additional Options Depending on application: -- Main motor power from 30 - 75 HP; 4" Max. cutting height (requires 75 HP motor); -- Variable feed speed; Non-marking Polyurethane contact feed rollers; -- Additional arbors; "QUICK CHANGE" arbor system (see video); -- "Pigtail" quick change Crosscut Saw System.Many more tooling & configuration options available upon requestThis machine will cut a bundle (42 sheets) of 3/4" Plywood. PB, MDF or OSB into narrow strips in (4) minutes or less.NOTE: PRICING DOES NOT REFLECT FACTORY'S 7% MATERIALS SURCHARGE

Call for Price

Call for Price

$ 105,000

LIGNA 10" x 48" thin kerf guided gang. Complete with (2) 200 HP motors; two speed feed works; chromed and knurled rollers; splined arbor. In very good condition. Rollers and bearings replaced just prior to removal. No infeed or outfeed. Includes guide milling machine; puck mold; guides form 7/8" to 2"; shims; many saw blades in excellent condition. PRICE REDUCED to $105,000.

$ 28,000

LIGNA rosserhead debarker, model 848. Complete machine with bull wheels, 50 HP head motor, head with cutter bits, operators controls. Good condition. Offered as-is / where-is but loaded on your truck.

$ 36,000

8" x 48" Rosserhead debarker. Used very little, LIGNA Model 848, S/N: F162085. Heavy duty. 6 sets bull wheels mounted on 3 7/16" bearings, 36" on centers - (like new, not re-poured). 50 HP head motor powering 8 section carbide tooth head. Maximum length 20'. Base frame 12" WF beam. (6) x 1 1/2" thick kicker arms., 20 HP Hydraulic system for head traverse and log rotation. Heavy duty pivot system and electric panel included. Size approximately 35' x 9' wide x 7 1/2' tall. Operators controls. Machine in great condition, but has been sitting outside . Offered as-is / where-is and loaded on your truck. Price $36,000.00.

$ 36,000

LIGNA ALT Trimmer. OPERATOR ON RIGHT. Set up for "0" saw; from 8' to 16' on 2' increments. Has 4' and 6' saw areas. 7.5 HP motor and saw blade on ladders. 9 feed chains--hydraulically driven. PLC controlled. Includes: operators controls and hydraulic power unit; 2 air operated gates; 5 strand tipple system with dealer wheels and air operated tipple arms; 9 feed chains--hydraulically driven; 5 strand let down conveyor; 5 infeed side, even-end rolls. Doors need work but are included. Offered, as removed from service. $36,000.

Call for Price

$ 47,500

LIGNA 8X40 Multi-Blade Edger/Gang Saw. 40" Wide by 8" high opening. Specifications: -- Bottom saw edger with (5) blades. Powered by a 125 HP TEFC motor. -- Features stacked air cylinder setworks with independent shifting on (3) blades. -- Infeed table with pop-up chains and fence, outfeed rollcase. -- Includes: Powered infeed and outfeed steel roll conveyors.

.gif)